Let’s face it, modern life is unthinkable without everyday electronics powered by Li-ion batteries. Present-day phones, vacuum cleaners and speakers no longer have any cords but batteries inside. More and more of our everyday appliances are substituted by battery-driven versions: scooters and bikes, toothbrushes, and even headphones and watches became electric.

Yet the Li-ion batteries can and should be improved.

Does your phone have to be charged twice a day? Thinking of buying an electric car but concerned about a single-charge range? Afraid that low-battery charge on your headphones is going to ruin your day?

Granode Materials exceptional battery solution has a potential to increase the energy density of rechargeable batteries and free your mind from thinking about chargers that often. It’s a game changer with a longer-lasting effect!

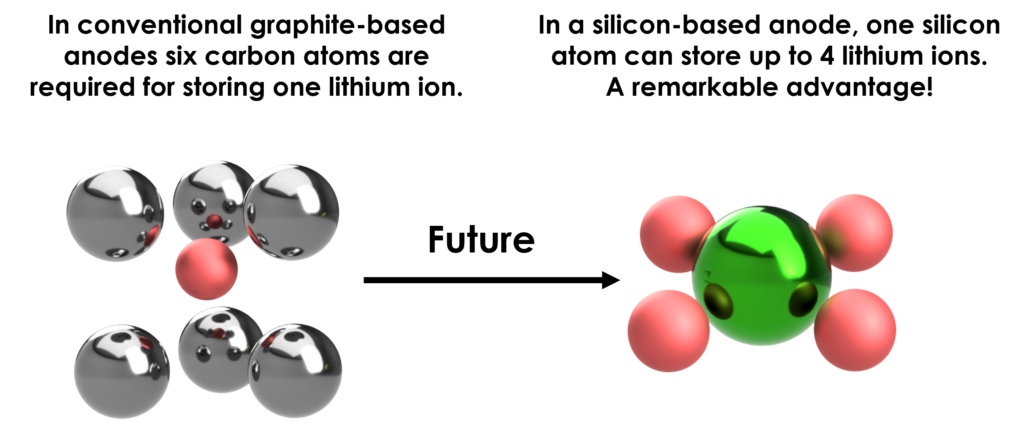

Silicon as anode material is known for several decades but rarely made it out of the lab testing due to a number of challenges associated with silicon-based anodes for Li-ions.

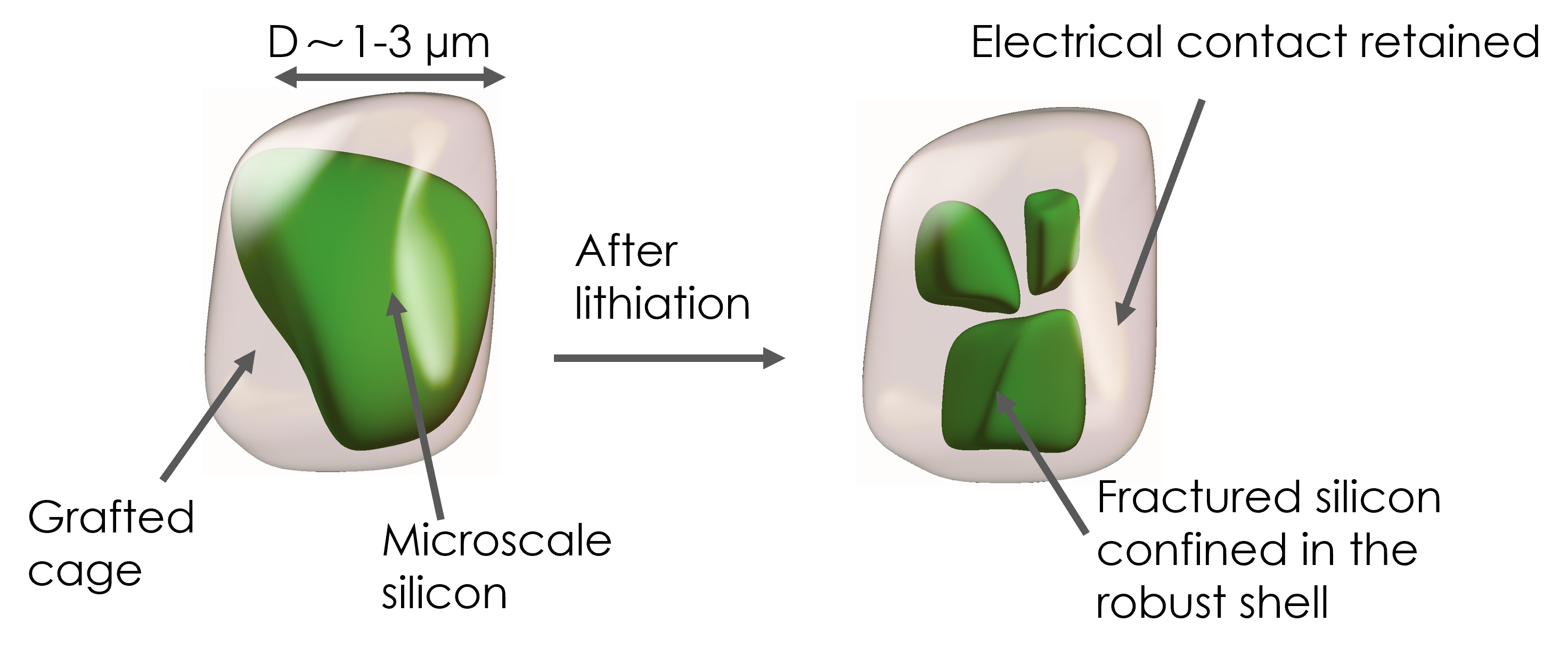

Our unique approach to silicon-based anodes treatment solves commonly known problems associated with silicon including particle pulverization after several cycles of lithiation-delithiation and caused by this loss of conductivity and exacerbate side reactions.

The grafted cage imparts its mechanical strength, electrical conductivity and chemical stability to microscale silicon particles. The mechanically flexible cage confines the violent expansion and fracture of silicon microparticles and electrically connects the ruptured particles.

Li-ion batteries on the market based on battery-grade graphite

Batteries of the future based on Granode Materials silicon-based anodes

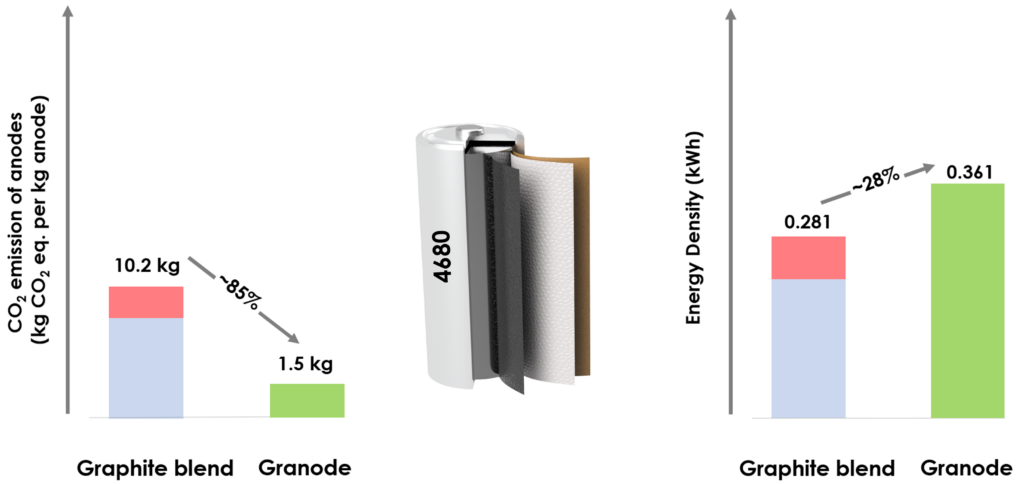

Energy density is limited and often restricted to charge capacity of graphite.

5-8 times higher charge capacities of Granode Materials anodes can provide you with up to 28% higher energy densities that are available for the existing battery anodes.

High CO2eq emissions on raw materials extraction, purification and production. Around 50% of the carbon footprint for conventional batteries production are associated with anodes.

Carbon footprint of raw materials extraction and treatments is reduced by 85% with Granode Materials silicon-based anodes technology.

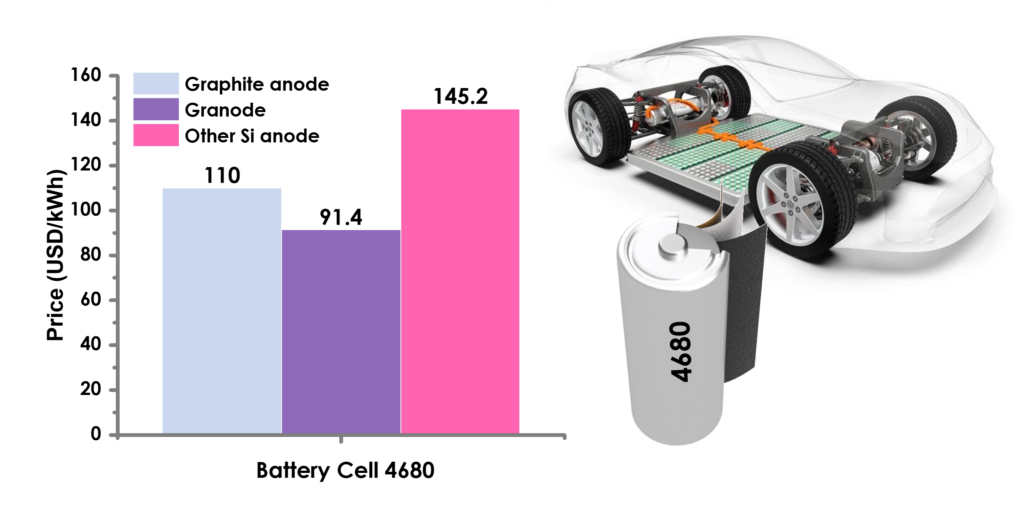

High costs associated with battery-grade graphite production and transportation.

EU-sourced materials are used for Granode Materials solution with cheap and abundant silicon dominating in the anodes.

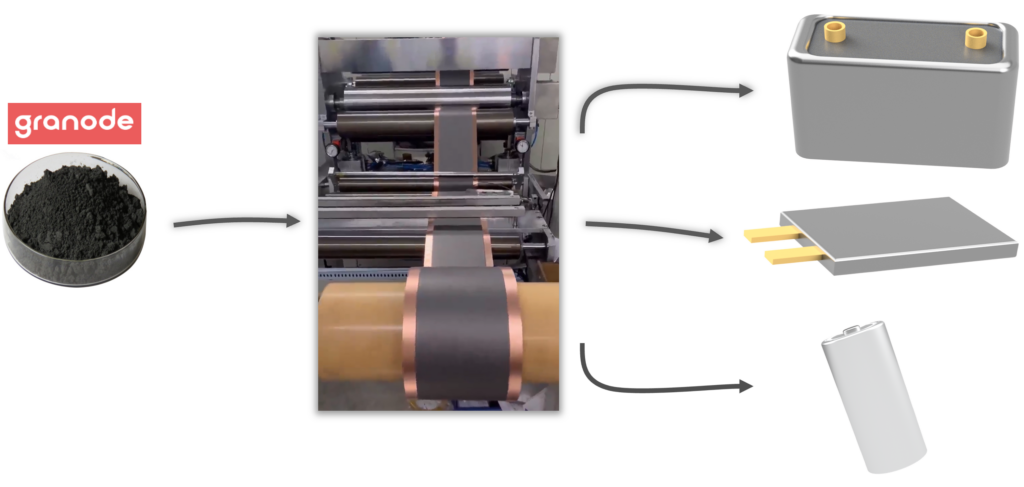

Our silicon-based anodes provide remarkable electrochemical performance, and it is a “plug-and-play solution” – we offer seamless compatibility with the current battery manufacturing technology. Switch to Granode Materials anodes to make future happen!